The Task:

In January 2011 the Oxley Creek STP was inundated by flood waters. The main contract for the design, supply, construction and commissioning of the flood affected Stages 1–4 of the plant was recently won by Monadelphous Engineering. EPCO Australia and Monadelphous have a long standing relationship, working together on projects such as NSW Public Works decanter installations for Cowra WWTP, Nambucca Heads WWTP and Wallerawang WWTP, Bundaberg Regional Council Bargara WWTP aeration and clarifier upgrade and Lake Cathie/Bonny Hills STP clarifier installations.

EPCO was tasked by Monadelphous with rehabilitating eight (8) clarifier mechanisms by modifying them to be more resilient to floods up to the Q100 level. This included the installation of:

- Four new bridges

- Four refurbished bridges

- Eight new handrails

- Weir plates on four of the clarifiers

- Eight new centre columns

- Cathodic protection for all columns

- Eight new drives

- Eight raised platforms for the switch boards

- Modification work to eight EDI chambers

- Launder Covers for Eight Clarifiers

- Sixteen scum boxes

Key Successes:

This project required the team to modify the design of 25+ year old mechanisms to meet current engineering standards along with meeting the new flood resilient design requirements. It also required complex project management and logistics (getting all materials to site on time). We’re very proud to have succeeded in all areas.

Challenges We Overcame:

Our client specified that the centre columns needed to be concrete lined painted mild steel with galvanic anode cathodic protection. This presented challenges in lining a steel pipe that has slots cut in at the top of the column (for the influent to discharge into the clarifier), as concrete lining is normally done by spinning them on solid pipes. Additionally the galvanic anode cathodic protection meant the rehabilitated Energy Dissipating Inlet could not slip over the column easily and had to be cut in half and reassembled. Despite these challenges the centre columns were delivered in accordance with the tight specification.

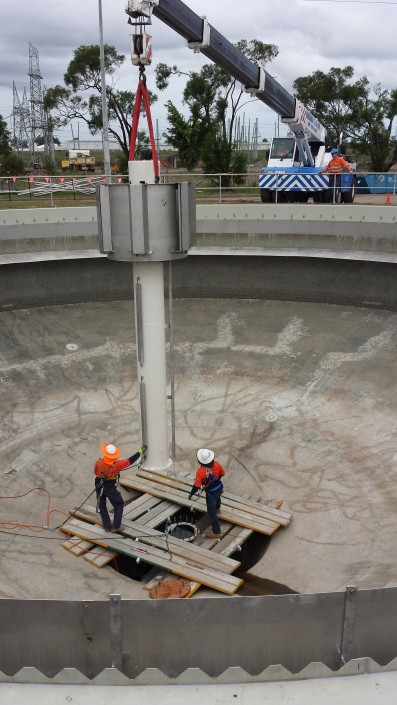

The floor of the clarifier was between 15 and 20o , a typical design for clarifiers from the 1960s. This presented installation challenges as the normal practice of using elevated work platforms inside the clarifier tank couldn’t be used. The installation methodology was adjusted to use a man box support from a mobile crane (refer to attached photo).

Another challenge was working on a site that was busy with multiple sub-contractors working in parallel on different parts of the STP. This made planning (and keeping the site clean and tidy!) difficult, but carefully working through the logistics allowed us to find solutions.

Special Considerations:

This project was unique because EPCO installed stainless steel launder covers, each weighing less than 20 kg. The stainless steel covers, while heavier than the traditional FRP covers represents a more economical solution and achieves the same design life and process objectives.

This was also the first time, in over thirty years, that we worked on eight at once!

The Bottom Line:

EPCO Australia is proud of this project because it represents the first time since 1979 that we have installed eight (8) clarifier mechanisms on the same site at the same time. Our Project Manager stepped up to the plate and excelled at scheduling and planning a complicated operation that resulted in a professional outcome that pleased the client. We are proud to say we lived up to brand promise, delivering on budget and on time.

What Does That Mean to You?

At EPCO Australia we are always ready for the next challenge.

- Want to learn more about the work we did on this project?

- Do you have a project that we may be able to help with?

- Email us today at [email protected] and talk to one of our friendly staff to see how we might be able to use our expertise to help you.